Push-Pull attachment

The Push-Pull attachment handles Slip Sheets

The Push-Pull Attachment Manipulates Slip Sheet Pallets

The Push-Pull attachment was specifically developed to handle slip sheets. It uses a hydraulic function to operate a faceplate and a gripper. It can easily be attached to any standard fork lift, and is certificated by ISO 9001. The maximal carrying capacity is 1.5 tonnes.

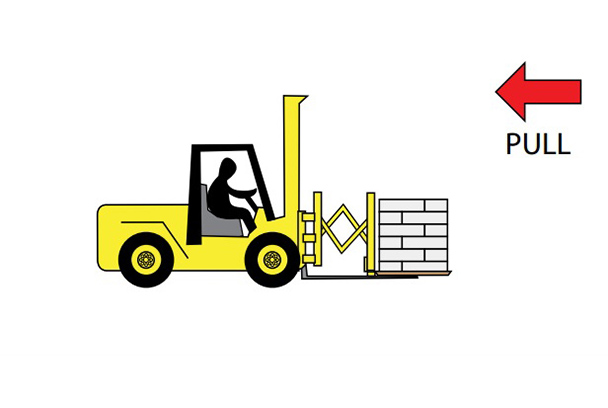

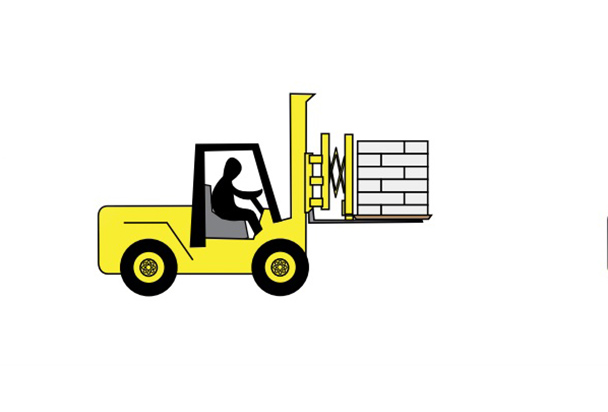

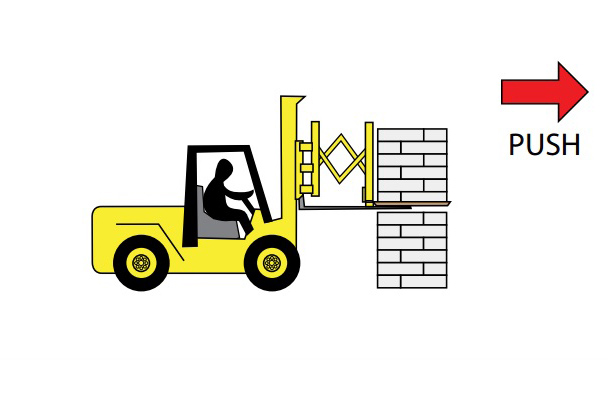

Handling by Push-Pull Attachment

The Push Pull attachment replaces standard forks, and is connected to the forklift via hydraulic pipe. Once you’ve got it attached, the forklift is ready to manipulate slip sheets. The faceplate and its gripper are ejected to clasp the channeling on the slip sheet pallet. The faceplate pulls the Slip Sheet pallet onto flat forks, and that’s it. The forklift is easily loaded and goods get transferred. Unloading works the same way. The faceplate pushes the Slip Sheet pallet onto the container or truck, and there you are - it’s ready for shipping!

Principles of Mounting the Push-Pull Attachment

CARRIAGE MOUNTING

The Push-Pull attachment is clipped onto the forklift’s carriage. This is also known as permanent mounting. The carriage mounting is more economical for companies that use palletless handling constantly for loading or unloading containers. For more information, please see the demonstration video here.

FORK MOUNTING

The Push Pull attachment is adapted to fit onto the standard forks of a forklift truck. This type of mounting is more economical for companies that don’t use slip sheets frequently because of the versatility. Please see the demonstration video here.

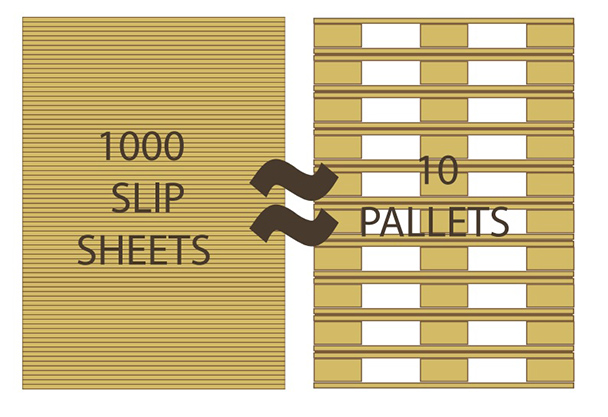

Applications for Slip Sheets and Push-Pull attachment

Slip sheets can be used in any type of industry. Export companies are an excellent match for our slip sheets in a process we like to call palletless handling. Slip Sheets can easily replace a one-way wooden pallet, thus reducing the cost of transport and increasing profits.